How to Boost Excavation Workflows and Productivity with Topcon's X-53x

Whether it’s trenching, flatwork, or more complex designs, with the X-53x you’ll dig to design every time – completing jobs in less time by eliminating over digging and costly rework.

Topcon’s X-53x system for excavators adds hydraulic control for fully automated digging and is designed to be easily upgradeable from the 2D and 3D systems. Once you’ve experienced the X-53x, it’ll make everything else seem like digging with a shovel. Topcon has even built a self-learning capability into the X-53x, so the system will figure out the best balance on the hydraulics settings, to get the ideal performance out of the machine.

Here are the key benefits to the X-53x:

1) Boost excavation workflows and productivity

Using 3D machine control workflows, you’ll be able to improve the productivity, accuracy, and profitability of your projects. Harnessing the power of fully automated GPS excavator control means that even relatively inexperienced operators can cut trenches, slopes, embankments and complex contours – often without the need for a finish dozer or grader to clean up the work.

By combining precise GPS positioning technology with advanced sensors, controllers, and simple onboard software, the X-53x is going to give you productivity improvements of 30% or more. Your experienced operators will love working with greater ease, and your beginners will look like a pro in no time.

2) Integrated power

Calibrating a GPS control system requires exceptionally precise measurements of the machine, but on the X-53x the calibration is done wirelessly using a total station and stored in an app on the machine. The X-53x system features fully integrated, multi-constellation GR-i3 receivers for precise positioning of the boom, stick and bucket, and you can even program the size and geometry of different buckets into the system, and choose your bucket with a touch on the screen. The GR-i3 is designed as an integrated GNSS receiver and antenna, providing powerful performance in harsh environmental conditions.

The X-53x is intuitively designed to feel like a natural extension of the operator, and convenient fingertip button controls on the joysticks provide instant access to the automatic features. The operator decides the exact moment to engage automatic grade depth and bucket angle assistance, giving them unmatched control for maximum productivity.

3) Two options depending on your needs:

The X-53x system comes in two options: Indicate and Auto. If you choose to go with the X-53x Indicate and discover you need additional features, you can upgrade to the Auto.

X-53x Indicate

The X-53x Indicate system provides real-time, dynamic on-screen bucket location and design views.

- Cut grade faster and more accurately

- Create, cut, and check complex designs from the cab

- Increase safety by removing the grade checker from the trench

X-53x Auto

Upgrading to the “Automatic” system helps your operator automatically control the digging depth and bucket angle when inside a working window, and they can easily execute imported design files or create a custom design from the cab of the excavator using the bucket to take topo shots.

- Automatic system engages inside a configurable working window

- Capability to use imported designs or create them “on the fly”

- Lock bucket attack angle

- Bucket follows complex designs by simply pulling back on the left joystick

- Support for boom automation in tilt/rotator applications

Visit us at Fieldays 2021 to check out the X-53x Auto Excavator System in action

At Fieldays you’ll be able to see live demos of:

- X-53x - with Steelwrist rotating hitch on 14T Volvo

- X-53x - with new LPS total station and swing boom

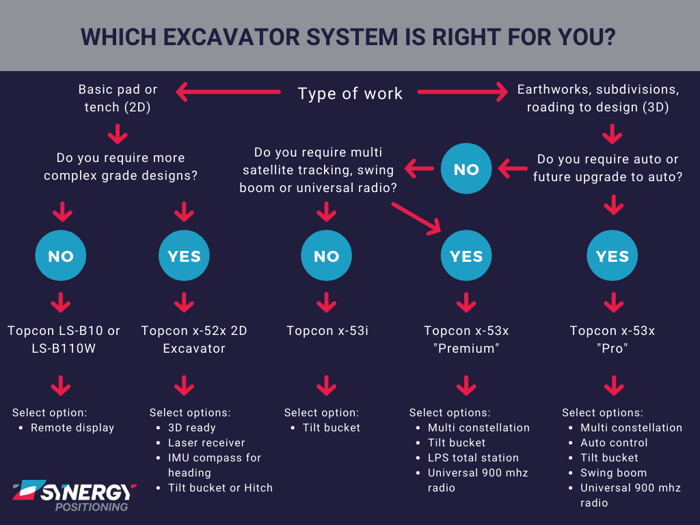

Not sure which Excavator System is right for you? Use this handy flowchart to figure out which option is best suited for your excavating needs:

Come and visit us at Fieldays 2021 to take advantage of our epic deals on next-gen Topcon Machine Control systems. Or contact us now to beat the rush and install today.