Our Top Tips to Increase the Accuracy of Your Machinery

Machine control can be applied to equipment and machinery for paving, milling road resurfacing, excavating, surface grading and other site work - and allows for much more accurate positioning using technology.

The positional accuracy of machine-controlled equipment can be defined as how precisely its axes can follow intended paths to commanded end points while under load. Ensuring your machinery is operating as precisely as possible is going to add significant benefits and cost-saving to your projects.

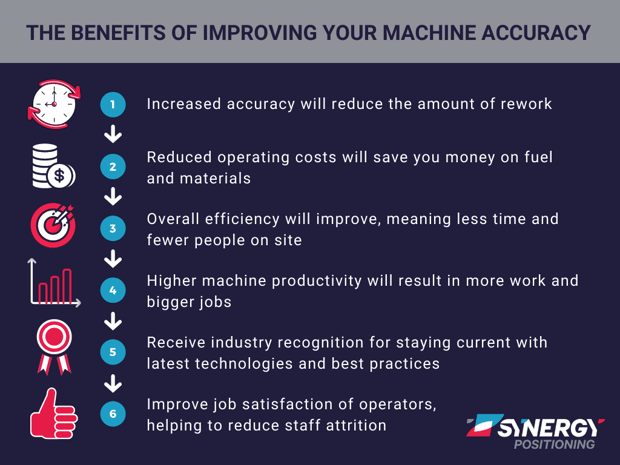

What are the benefits to Improving Your Machine Accuracy?

As you can see, the benefits of prioritising your machine accuracy is not just at the site-level, but will result in company-wide improvements, supporting your business growth in the long run.

So the question is - how can you improve the accuracy of your machinery?

Top Tips to Increase Your Machine Accuracy

Machine maintenance

Ensuring your machinery is well maintained will have a huge impact on machine accuracy. The accuracy of a machine may degrade over time as it is used, and an incorrectly set-up machine may degrade even faster. Factors like flatness, perpendicularity, parallelism and straightness of interfacing surfaces determine the machine tool’s basic accuracy, and reducing these geometric errors allows for other errors to be isolated and corrected more easily. Ultimately, preventative maintenance is more economical in the long-term than responding to breakdowns.

Use a Topcon machine control system

To use Topcon mmGPS, GPS receivers are mounted on the outside of machines and additional sensors are used to get accurate positioning. A separate GPS receiver is set up as a base station to provide RTK (real-time kinematic) corrections to the machine via UHF radio or 3G cellular network. Check out this case study of how Topcon mmGPS enabled unprecedented machine control accuracy during the construction of Hamilton’s biggest roading project ever.

Maximise your Topcon system

Topcon machine control systems are flexible and can be upgraded depending on the application and tolerances required. While GPS is accurate enough for most bulk earthworks, tighter tolerances can be achieved through the Topcon mmGPS or LPS (local positioning system) solutions. And by fitting more than one machine on-site with GPS receivers, you can move the control components between machines as they are required, giving you maximum system utilisation and a greater return on investment.

Machine Accuracy in Action

Designed for excavators, the X-53x automatic is a new edition of Topcon’s 3D modular control system, and it adds hydraulic control for fully automated digging.

How does it work?

Using four sensors on the body, boom, stick and bucket, combined with a GPS antenna on the back of the machine to give you roll and pitch, your excavator can dig fully automated to a design loaded into the machine’s control panel.

How does this technology ensure accuracy?

Calibrating a GPS control system on an excavator requires exceptionally precise measurements of the bucket, stick, boom and position of the machine. Instead of using a tape measure and typing in the measurements (with plenty of opportunities for inaccuracy and human error), the Topcon’s X-53x is done wirelessly using a total station and is stored in an app on the machine. This also allows you to program the size and geometry of unlimited different buckets into the system, so you can choose your bucket with a touch on the screen.

Equipping your excavator with fully automated GPS control means that even relatively inexperienced operators can cut trenches, slopes, embankments and complex contours- often without the need for a finish dozer or grader to clean up the work. If you’re interested in finding out more - read about the Topcon X-53x here.

Here at Synergy Positioning, we’ve seen how companies of all sizes have improved productivity and reduced costs thanks to the benefits of machine control products and technology. Check out our Roadmap to your Ideal Solution to see how we can help your business.