Topcon's Hybrid Positioning: Complete Connectivity On Site

Topcon has made far-reaching developments in the positioning industry by combining its advanced optical total station technology, with industry-leading signal processing and performance. These hardware solutions, integrated with MAGNET Field software, come together to create Hybrid Positioning - a constellation of technologies built to boost productivity and profitability through seamless connectivity.

GT Series Total Station with the FC-6000 Field Controller

As the smallest and lightest robotic total station, the Topcon GT Series is designed for complete job site flexibility alongside powerful accuracy. Single-person operation is made easy with the simple set up and intuitive digital processes, without sacrificing full feature functionality and advanced technology. Driven by the Ultra-Sonic Motors (USM), the instrument has a turning speed of 180 degrees per second, providing an impressive tracking speed of 20 degrees per second - making the GT series the fastest instrument in the industry.

Utilising a combination of the most advanced signal processing through the GNSS receiver, with Topcon’s optical total station technology using powerful EDM performance, Hybrid Positioning is achieved with a single touch of a button on the highly intuitive field controller. The GNSS location enables the instrument to lock onto the prism faster, automatically resecting the total station, and providing a method of measurement even when the line of sight to the instrument is obstructed by objects like tree coverage or awnings.

The GT has the ability to set control, check previous work, gather topographic data, and perform layout - making it a fully integrated system for maximum versatility on site. Operators are able to achieve a much higher level of productivity compared to traditional systems, completing up to three jobs in a day when they might usually only complete one.

Hiper VR GNSS Receiver

Hybrid Positioning simply requires an incoming position from a GNSS receiver - this is where Topcon’s Hiper VR comes in. The hybrid system combines both GNSS positioning and optical robotic measurements into one rover pole measurement point, allowing the operator to quickly move around a construction site, while still achieving maximum accuracy. The Hiper VR is compact and lightweight, but its rugged build means it can withstand even the toughest field environments.

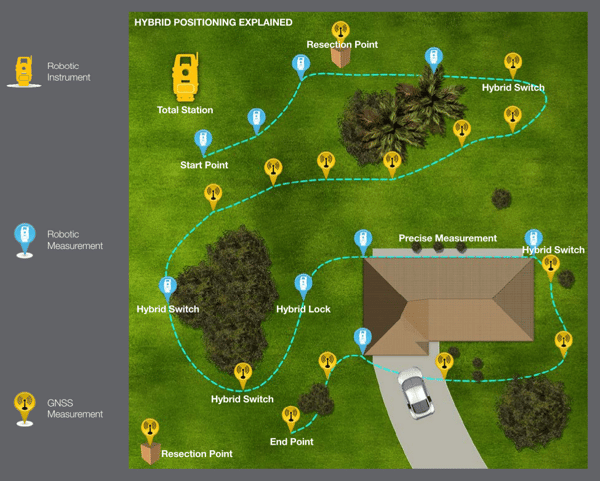

In the diagram below, you can see how the system uses Hybrid Positioning to transition between robotic measurements and GNSS measurements. The instrument picks up a robotic measurement until the line of sight is potentially obstructed by some trees, in which case the operator would simply implement the hybrid switch function on the controller to pick up a GNSS signal - without the need for a new setup. The hybrid lock function turns the instrument back towards the prism location to quickly regain prism tracking, and allow the operator to record more shots.

MAGNET Software

With MAGNET Field data collection software, all Hybrid Positioning components come together to make a fully integrated solution. Seamlessly upload data collected out in the field onto the cloud storage, to be shared with managers for review, CAD technicians, and other stakeholders in the office, to effortlessly collaborate on a project. The team in the office can also log in to the system and see what’s happening out in the field in real-time, and collect data as it happens.

MAGNET Field and Office software streamlines the traditional workflow and has a massive impact on productivity. The system also provides valuable insights for better site management and increased profitability, thanks to the powerful and far-reaching capabilities of the software. Take a look at how the team at Velcon Engineering and Surveying used Hybrid Positioning to optimise their operations.

Hybrid Positioning is focused on using a combination of Topcon’s advanced technology to achieve the best, most accurate results quickly, and distributing the data efficiently so your team can optimise results. The versatility of the systems working together saves time while maintaining the highest level of accuracy achievable.

If you’d like to know more about Hybrid Positioning systems for your next project, get in touch with the team to see a demo of all the components in action today.